>> Key Advantages & Features

As a core 3500 machinery protection system module, the 3500/42M offers ±0.1% full-scale accuracy for seismic vibration and proximitor position. It detects subtle anomalies (0.001 mm axial displacement/0.1 mm/s vibration) in real time, cutting unplanned downtime by 40%—ideal for power, oil, and gas rotating equipment.

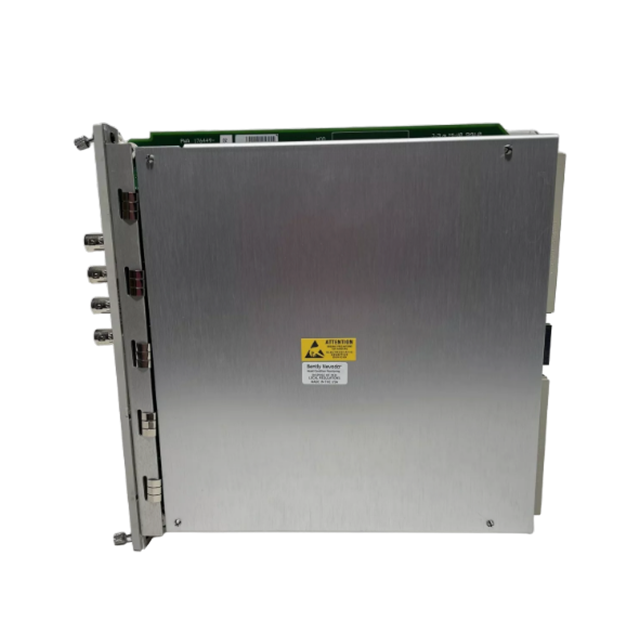

The 3500/42M combines proximitor tracking and seismic monitoring in one module, fitting seamlessly into the 3500 rack. It saves 30% rack space, simplifies wiring, reduces installation time by 25%, and works with existing 3500 components—great for retrofits or new setups.

Built for harsh environments, the 3500/42M operates at -40°C to 70°C, resists 5 g vibration (10-2000 Hz), and has an MTBF of over 150,000 hours. It meets IEC 61508 SIL 2 standards, ensuring dependability for turbine/compressor protection.

With configurable alarms, the module sends data to the 3500 rack in <100 ms for instant alerts. It stores 12 months of historical data for predictive maintenance, extending equipment lifespan by 20% and lowering annual maintenance costs by 35%.

The 3500/42M supports in-rack calibration (cutting time by 50%) and integrates with Bently Nevada’s System 1® software. Its intuitive interface minimizes technician training, enabling fast deployment for proximitor seismic monitoring sites.