Are you confused about the GE Mark VI and Mark VIe systems? Understanding their differences is crucial for effective decision-making. In this article, we’ll explore the key distinctions between these two systems, their architectures, and their applications. You’ll learn how these differences impact performance and reliability in various industries.

Understanding the GE Mark VI and Mark VIe Systems

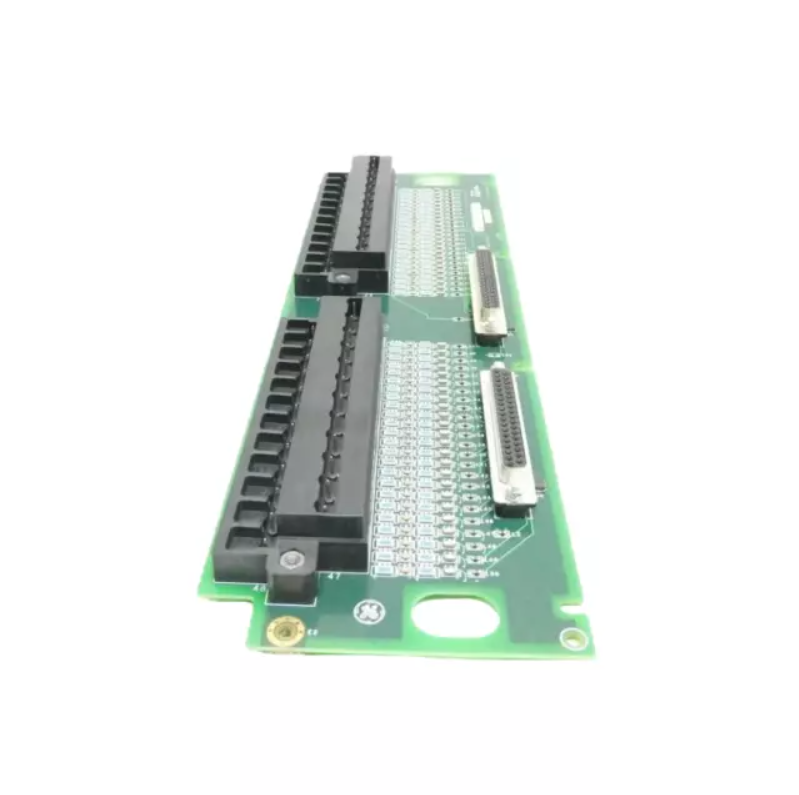

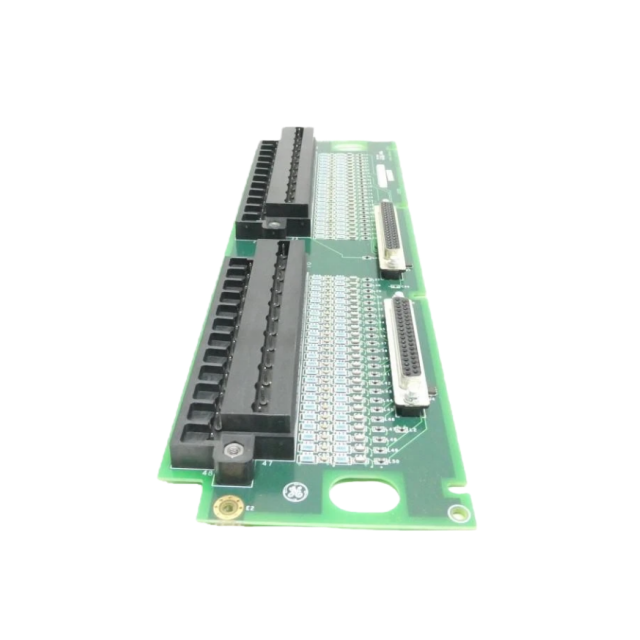

Overview of GE Mark VI

The GE Mark VI system has been a cornerstone in industrial automation since its introduction. Developed over several years, it is specifically designed to control and monitor various types of turbines. Its VME-based architecture ensures reliable performance, while the centralized control logic simplifies operations. This system is particularly well-suited for medium to small turbine control scenarios, making it a popular choice in numerous industries.

Key Features and Specifications

● Architecture: VME-based, which allows for robust communication between components.

● Control Logic: Centralized, enabling straightforward management of turbine operations.

● Applications: Widely used in power generation, oil and gas, and manufacturing sectors.

The GE Mark VI system's reliability and ease of use have made it a trusted solution for many operators. It excels in environments where consistent performance is critical, providing a solid foundation for turbine control.

Overview of GE Mark VIe

In contrast, the GE Mark VIe system represents a significant evolution in control technology. This system introduces an Ethernet-based architecture, allowing for enhanced communication and integration capabilities. The shift to a distributed control model means that tasks can be managed across multiple nodes, improving flexibility and response times.

Key Features and Specifications

● Architecture: Ethernet-based, which facilitates faster data transfer and connectivity.

● Control Capabilities: Distributed, allowing for localized decision-making and processing.

● Advancements: It offers enhanced performance and flexibility compared to the Mark VI, catering to modern industrial needs.

The GE Mark VIe is designed for the future, supporting modern industrial IoT applications. Its ability to connect seamlessly with other systems makes it an ideal choice for industries looking to adopt smart technologies.

Comparison of Features

Feature | GE Mark VI | GE Mark VIe |

Architecture | VME-based | Ethernet-based |

Control Logic | Centralized | Distributed |

Typical Applications | Medium to small turbines | Large turbines and IoT applications |

Performance | Reliable with proven track record | Enhanced flexibility and performance |

The table above highlights the key differences between the two systems. As industries evolve, the need for more advanced control solutions has never been greater. The GE Mark VIe stands out as a solution that meets these demands, offering a pathway to smarter operations.

In summary, both systems serve distinct purposes within the industrial landscape. The GE Mark VI is a reliable choice for traditional applications, while the GE Mark VIe paves the way for future advancements in automation and control.

![GE Mark VI GE Mark VI]()

Core Differences Between GE Mark VI and Mark VIe

System Architecture

GE Mark VI Architecture

The GE Mark VI system features a centralized control architecture. This design relies heavily on VME racks for communication between components. While this architecture has been effective, it does present some limitations in scalability. As operations grow, the ability to expand the system becomes a challenge, often requiring significant upgrades to accommodate increased demand.

GE Mark VIe Architecture

In contrast, the GE Mark VIe employs a distributed control architecture. This modern approach utilizes Ethernet I/O networks and embedded processors, providing greater flexibility and local data processing capabilities. It allows for easier integration of new technologies and supports a more modular design, making it ideal for evolving industrial environments.

Communication Protocols

GE Mark VI Communication Protocols

The GE Mark VI uses a proprietary IONet protocol for communication. While this protocol ensures reliable performance, it has limitations in interoperability with third-party systems. This can hinder integration efforts, especially in environments where diverse systems need to communicate effectively.

GE Mark VIe Communication Protocols

On the other hand, the GE Mark VIe supports several open communication standards, such as Ethernet, Modbus TCP/IP, and OPC-UA. This flexibility enhances data sharing efficiency and facilitates integration with Distributed Control Systems (DCS). Users benefit from a more interconnected system, which is essential for modern industrial applications.

Redundancy and Reliability

Redundancy in GE Mark VI

The GE Mark VI system incorporates triple modular redundancy (TMR) to enhance reliability. However, it faces limitations regarding I/O module redundancy, which can impact overall system performance. Additionally, it employs software-based fault tolerance (SIFT) mechanisms to mitigate risks, but these may not be sufficient in all scenarios.

Redundancy in GE Mark VIe

In contrast, the GE Mark VIe offers various redundancy configurations, including simplex, dual, and TMR setups. One notable advantage is the hot-swappable I/O modules, allowing for maintenance without system downtime. Its hardware-level fault detection enhances fault detection and diagnostics capabilities, making it a more robust choice for critical applications.

Scalability and Compatibility

Scalability of GE Mark VI

The GE Mark VI system supports a maximum of nine VME racks. While this is suitable for many applications, it limits integration with newer digital monitoring platforms. As industries evolve, this can pose challenges for users looking to upgrade their systems.

Scalability of GE Mark VIe

In contrast, the GE Mark VIe features modular expansion capabilities, allowing for easy upgrades and integration with new technologies. It supports multiple turbine control and enables online firmware upgrades, ensuring that the system remains current with industry advancements.

Cybersecurity Features

Cybersecurity in GE Mark VI

The GE Mark VI includes basic user access controls, but it lacks dedicated cybersecurity measures. This absence can pose risks, especially in interconnected industrial networks that are increasingly targeted by cyber threats.

Cybersecurity in GE Mark VIe

The GE Mark VIe, however, implements multi-layered security features. It includes role-based access control (RBAC), audit logs, and encrypted communication, ensuring compliance with modern industrial cybersecurity standards. This comprehensive approach significantly enhances the security posture of the system, addressing contemporary challenges in industrial automation.

Core Product Information

Key Components of GE Mark VI

Control Modules

The GE Mark VI system features the IS215UCVGH1A UCV controller, a critical component designed for high performance in turbine control applications. This controller is known for its robust specifications, which include advanced processing capabilities and reliable communication interfaces. One of the standout aspects of this module is its compatibility with earlier versions of the Mark VI system, allowing for smoother upgrades and integration. This backward compatibility ensures that existing installations can benefit from the latest technology without requiring a complete overhaul.

I/O Terminal Boards

The I/O terminal boards in the GE Mark VI system serve essential functions, including analog output and input. These boards are designed to handle various signal types, enabling effective data collection and control. Additionally, they come equipped with diagnostic capabilities and signal isolation features, which enhance system reliability. By isolating signals, these boards minimize interference and ensure accurate readings, which is crucial for maintaining optimal performance in industrial environments.

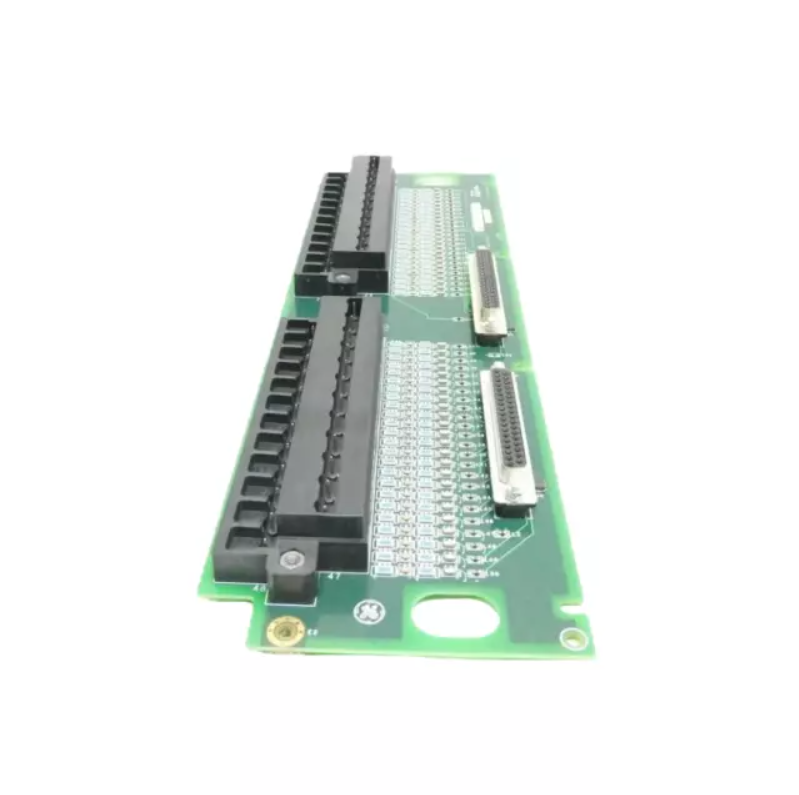

Key Components of GE Mark VIe

Control and Communication Modules

In the GE Mark VIe system, the IS420ESWBH1A network switch plays a pivotal role. This module enhances communication and control efficiency within the system. By facilitating faster data transfer and reducing latency, it ensures that all components can communicate effectively. The switch's design supports a variety of communication protocols, making it versatile for different applications. This efficiency is essential for modern industrial operations, where real-time data is critical for decision-making.

I/O Module Series

The GE Mark VIe includes a series of high-performance I/O modules that are tailored for diverse applications. These modules feature advanced capabilities such as signal conditioning and fault detection. Signal conditioning ensures that input signals are processed accurately, while fault detection mechanisms quickly identify issues, reducing downtime. This series is designed to support complex industrial operations, making it a valuable addition to any modern control system.

Component | GE Mark VI | GE Mark VIe |

Control Module | IS215UCVGH1A UCV controller | IS420ESWBH1A network switch |

I/O Terminal Boards | Analog output/input, diagnostic features | High-performance I/O modules |

Key Features | Compatibility with earlier versions | Signal conditioning, fault detection |

This table summarizes the key components of both systems, highlighting their distinct features and roles. The GE Mark VI focuses on reliability and compatibility, while the GE Mark VIe emphasizes advanced communication and performance capabilities, catering to the needs of modern industries.

![GE Mark VIe GE Mark VIe]()

Competitive Analysis

Comparison with Competing Systems

Redundancy and Reliability

When we look at redundancy and reliability, the GE Mark VI and Mark VIe systems stand out compared to their competitors. Many systems in the market offer redundancy features, but GE's approach is particularly robust. For instance, both the Mark VI and Mark VIe utilize triple modular redundancy (TMR), ensuring that critical functions remain operational even in the event of a failure. This level of redundancy is a unique selling point, as it provides peace of mind in high-stakes environments where downtime can be costly.

In comparison, some competing systems may only offer dual redundancy, which can be less effective in critical applications. GE’s systems are designed for reliability, making them a preferred choice for industries that cannot afford interruptions.

Communication Protocols

Communication is another area where GE systems excel. While many competitors utilize proprietary protocols, GE supports a range of open communication standards, including Ethernet and Modbus TCP/IP. This flexibility allows for easier integration into existing networks and enhances interoperability with other systems.

Competitors often face challenges when trying to integrate their systems into diverse environments, limiting their effectiveness. GE's commitment to open protocols means that users can seamlessly connect their systems, facilitating better data exchange and operational efficiency.

Strengths and Weaknesses

Advantages of GE Mark VI

One of the key advantages of the GE Mark VI system is its compatibility with older systems. This makes upgrades straightforward and minimizes the need for extensive retraining or system overhauls. Users can maintain their existing infrastructure while benefiting from the latest technology, which is a significant plus in many operational environments.

Moreover, the Mark VI has a proven track record of reliability. Many users have reported consistent performance over years of operation, reinforcing the system's reputation as a dependable choice for turbine control.

Advantages of GE Mark VIe

The GE Mark VIe takes the strengths of its predecessor and enhances them further. Its advanced architecture supports better data processing and communication, which is essential for modern industrial applications. Additionally, the Mark VIe boasts enhanced cybersecurity features, addressing growing concerns about data security in interconnected environments.

Flexibility is another major benefit of the Mark VIe. It can be deployed in various configurations, accommodating the specific needs of different operations. This adaptability makes it a suitable choice for a wide range of industries.

Areas for Improvement

Despite its strengths, the GE Mark VI does have limitations. One notable area is scalability; as operations grow, the system may require significant upgrades to meet increased demand. This can pose challenges for companies looking to expand their capabilities without investing heavily in new systems.

Additionally, while the Mark VI has basic cybersecurity measures, it lacks the comprehensive protections found in newer systems. In today's interconnected environments, additional security measures are necessary to safeguard against potential threats. As industries increasingly rely on digital solutions, enhancing cybersecurity will be crucial for maintaining trust and reliability.

Aspect | GE Mark VI | GE Mark VIe | Competitors |

Redundancy | Triple modular redundancy (TMR) | Enhanced TMR with hot-swappable components | Often dual redundancy |

Communication Protocols | Supports open standards | Extensive protocol support | Proprietary protocols |

Compatibility | High compatibility with older systems | Flexible deployment options | Limited interoperability |

Cybersecurity | Basic security features | Advanced cybersecurity measures | Varies widely, often less robust |

This table highlights the strengths and weaknesses of the GE Mark VI and Mark VIe systems compared to their competitors. It provides a clear overview of what makes GE systems a solid choice for many industries while also pointing out areas where improvement is needed.

Conclusion

The GE Mark VI and Mark VIe systems differ significantly in several areas. The Mark VI offers proven reliability and compatibility with older systems. In contrast, the Mark VIe features advanced architecture and enhanced cybersecurity.

When choosing between the two, consider your specific operational needs. Assess factors like scalability, redundancy, and communication protocols.

Take the time to evaluate your requirements to make an informed decision about which system best suits your operations.

FAQ

Q: What industries commonly use GE Mark VI and Mark VIe?

A: Industries such as power generation, oil and gas, and manufacturing commonly use the GE Mark VI and Mark VIe systems.

Q: How do the maintenance requirements differ between the two systems?

A: The GE Mark VI requires less frequent maintenance due to its simplicity, while the Mark VIe has more complex components needing regular updates.

Q: Can GE Mark VIe easily replace GE Mark VI in existing setups?

A: Yes, the Mark VIe can replace the Mark VI, but some modifications may be necessary for full integration.

Q: What are the costs associated with upgrading from GE Mark VI to Mark VIe?

A: Upgrade costs vary based on system size and complexity, often requiring a significant investment in new hardware and software.

Q: How does the redundancy configuration impact system reliability?

A: Redundancy configurations enhance reliability by ensuring continuous operation during component failures, particularly in critical applications.