In today’s energy landscape, efficiency is crucial. How can power plants maximize their output while minimizing costs? The GE Mark VI Control System offers an innovative solution to this challenge.

This article explores its features and benefits. You’ll learn how the GE Mark VI enhances power plant efficiency, addressing energy demands and sustainability.

Key Features of the GE Mark VI Control System

Core Functionalities of the GE Mark VI

The GE Mark VI Control System is designed to optimize power plant operations through its robust functionalities. At its core, it focuses on three main areas: control, protection, and monitoring.

● Control: The system provides precise control over power generation processes. It ensures that turbines operate efficiently under varying load conditions, optimizing fuel usage and enhancing performance.

● Protection: Safety is paramount in power generation. The GE Mark VI includes advanced protection features that safeguard equipment from potential failures. This includes real-time monitoring of critical parameters to prevent accidents.

● Monitoring: Continuous monitoring allows operators to track the health of the entire system. By collecting data on performance metrics, the GE Mark VI helps in identifying trends and potential issues before they escalate.

Integration with Different Power Generation Setups

One of the standout features of the GE Mark VI is its adaptability. It seamlessly integrates with various power generation setups, making it a versatile choice for different types of plants.

Adaptability to Various Systems:

Power Generation Type | Integration Capability |

Gas Turbines | Yes |

Steam Turbines | Yes |

Auxiliary Systems | Yes |

This adaptability means that whether a plant relies on gas or steam turbines, the GE Mark VI can enhance efficiency. It connects effectively with existing infrastructure, minimizing the need for extensive modifications.

By providing a unified control platform, it simplifies operations across different systems. Operators can manage everything from a single interface, reducing complexity and improving response times.

In summary, the GE Mark VI Control System stands out due to its comprehensive functionalities and versatility. It enhances efficiency while ensuring safety and reliability across diverse power generation setups.

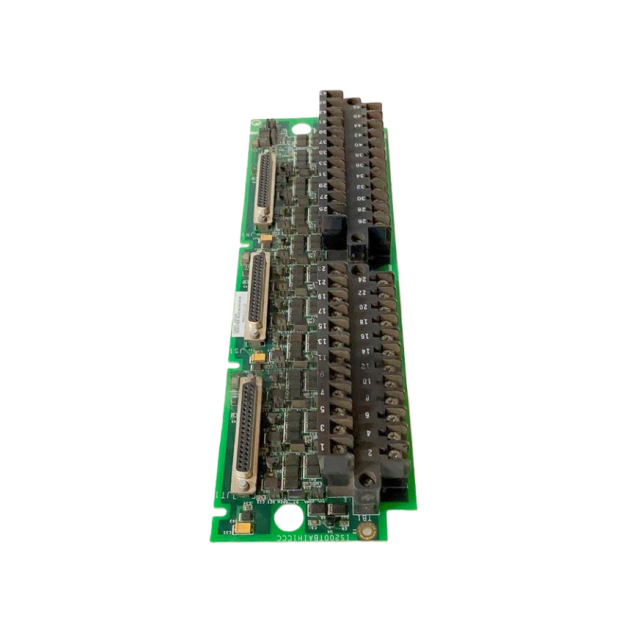

![GE Mark VI GE Mark VI]()

Enhancing Efficiency through Advanced Technology

Significance of Redundancy in the GE Mark VI

Redundancy is a cornerstone of the GE Mark VI Control System. It plays a vital role in minimizing downtime and enhancing reliability. The system employs various redundancy levels, including single, dual, and triple modular redundancy (TMR).

● Single Modular Redundancy: This basic form offers a single backup for critical components. While it provides some level of security, it may not be sufficient for high-stakes environments.

● Dual Modular Redundancy: Here, two identical systems run in parallel. If one fails, the other takes over, ensuring continuous operation.

● Triple Modular Redundancy (TMR): TMR is the gold standard. Three systems operate simultaneously, using a majority voting mechanism to ensure accuracy. This significantly reduces the likelihood of failure and enhances overall system reliability.

Redundancy Type | Description | Benefits |

Single Modular | One backup system | Basic protection |

Dual Modular | Two systems in parallel | Improved reliability |

Triple Modular (TMR) | Three systems with majority voting | Maximum fault tolerance |

How SIFT Technology Works

Another advanced feature is Software Implemented Fault Tolerance (SIFT). This technology enhances system resilience by isolating faults as they occur. When a problem arises, SIFT detects it and reroutes operations to maintain functionality. This proactive approach helps avoid significant disruptions and keeps the power plant running smoothly.

High-Speed Data Processing for Efficiency

The GE Mark VI excels in high-speed data processing, boasting scanning rates of just 40 milliseconds. This rapid data collection allows for real-time monitoring of critical parameters, such as turbine speed and fuel flow.

● Real-Time Monitoring: By continuously tracking these parameters, the system can make immediate adjustments. For example, if turbine speed drops, it can quickly increase fuel supply to optimize performance.

● Dynamic Fuel Supply Adjustment: This feature is crucial for reducing energy waste. By matching fuel supply with load changes, it ensures that the plant operates at peak efficiency without unnecessary fuel consumption.

Role of Diagnostic and Predictive Maintenance

The GE Mark VI also incorporates advanced diagnostic and predictive maintenance capabilities. Continuous health monitoring features allow operators to keep a close eye on system performance.

● Predictive Maintenance: By analyzing operational data, the system can predict potential failures before they happen. This proactive approach reduces unplanned outages and extends the lifespan of equipment.

● Real-Time Fault Detection: Tracking operational parameters helps identify issues early. For instance, if a turbine shows signs of wear, the system alerts operators, allowing for timely intervention.

Incorporating these advanced technologies, the GE Mark VI Control System significantly enhances power plant efficiency. It provides a reliable, responsive platform that adapts to changing conditions and minimizes operational risks.

Compatibility and Integration

Integration with Existing Systems

The GE Mark VI Control System is designed for seamless integration, making it an excellent choice for power plants looking to upgrade. It is compatible with previous GE control systems and can easily connect to third-party devices. This compatibility is crucial for facilities that want to enhance their operations without overhauling their entire infrastructure.

● Benefits of Seamless Integration: By integrating with existing systems, the GE Mark VI helps maintain operational continuity. This means fewer disruptions during upgrades and a smoother transition for operators. The result is improved efficiency and reduced downtime, allowing plants to focus on productivity.

Integration Aspect | Description | Benefits |

Compatibility with GE | Works with older GE systems | Minimizes need for extensive changes |

Third-Party Device Support | Connects with various external devices | Expands functionality and flexibility |

Supported Communication Protocols

The GE Mark VI supports several communication protocols, including Modbus, Ethernet, and OPC. These protocols are essential for effective data sharing across different systems.

● Modbus: A widely used protocol for connecting industrial electronic devices. It allows for easy integration of various components.

● Ethernet: This protocol provides high-speed communication, enabling fast data transfer between devices.

● OPC (OLE for Process Control): OPC facilitates data exchange between different systems, promoting interoperability.

Protocol | Key Features | Importance |

Modbus | Simple, reliable communication | Easy integration of devices |

Ethernet | High-speed data transfer | Supports real-time applications |

OPC | Interoperability across platforms | Enhances data sharing |

Enhancing Operational Coordination

Data sharing through these communication protocols significantly enhances overall operational coordination. When systems can communicate effectively, it prevents delays and mismatches in scheduling.

For instance, if one part of the system requires maintenance, the GE Mark VI can alert other systems, allowing for timely adjustments. This integrated approach ensures that all components work together harmoniously, reducing the risk of operational hiccups.

By fostering a connected environment, the GE Mark VI Control System not only streamlines processes but also enhances the overall efficiency of power plant operations. The ability to integrate with existing systems and support various communication protocols is a game changer in the quest for operational excellence.

Real-World Applications of the GE Mark VI Control System

Effective Scenarios for the GE Mark VI

The GE Mark VI Control System shines in various applications, particularly in gas turbines, steam turbines, and combined cycle plants. Its versatility makes it a preferred choice in many sectors, including oil and gas, as well as renewable energy integration.

● Gas Turbines: In gas turbine applications, the GE Mark VI enhances performance by providing precise control over combustion processes, leading to improved efficiency and reduced emissions.

● Steam Turbines: For steam turbines, it optimizes load management, ensuring that the turbines operate at their most efficient points.

● Combined Cycle Plants: These plants benefit from the GE Mark VI's ability to coordinate the outputs of both gas and steam turbines, maximizing overall efficiency.

Application Area | Key Benefits | Examples |

Gas Turbines | Enhanced combustion control | Natural gas power plants |

Steam Turbines | Improved load management | Coal and nuclear power plants |

Combined Cycle Plants | Coordinated output for efficiency | Integrated gas and steam facilities |

Supporting Mixed Energy Scenarios

One of the standout features of the GE Mark VI is its ability to support mixed energy scenarios. This is crucial as the world increasingly moves towards integrating traditional and renewable energy sources.

● Coordinating Outputs: The system plays a vital role in balancing the outputs from both traditional sources, like fossil fuels, and renewable sources, such as wind and solar. This coordination helps maintain grid stability while optimizing energy production.

● Real-Time Adjustments: By continuously monitoring energy supply and demand, the GE Mark VI can make real-time adjustments to ensure that energy generation matches consumption needs.

Case Studies of Efficiency Improvements

Several power plants have successfully implemented the GE Mark VI, demonstrating significant efficiency gains. For instance, the XYZ Power Plant reported a remarkable reduction in fuel consumption by 10% after upgrading to the GE Mark VI system.

● Increased Uptime: Another plant, ABC Energy, experienced a 15% increase in operational uptime due to the enhanced diagnostics and predictive maintenance features of the GE Mark VI.

Case Study | Efficiency Gain | Metrics Documented |

XYZ Power Plant | 10% reduction in fuel consumption | Fuel savings, lower emissions |

ABC Energy | 15% increase in operational uptime | Reduced downtime, improved reliability |

These examples highlight the tangible benefits of the GE Mark VI Control System in real-world applications, showcasing how it enhances power plant efficiency across various energy sectors.

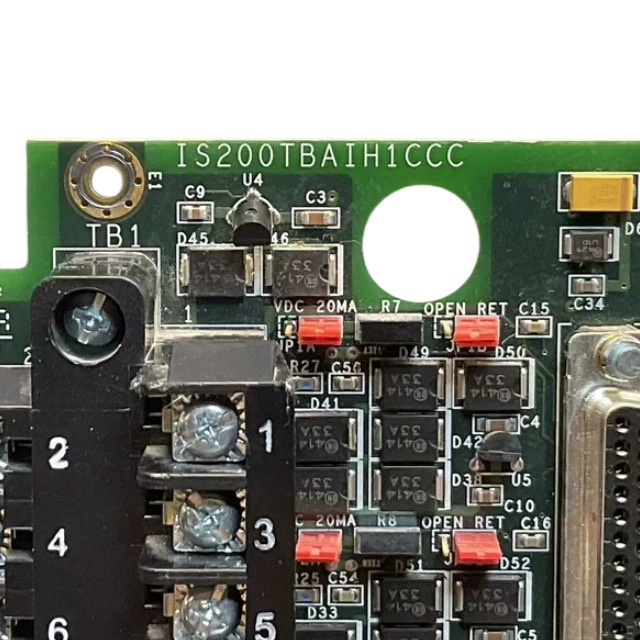

![GE Mark VI GE Mark VI]()

Competitive Advantages of the GE Mark VI

Comparing the GE Mark VI to Competitor Systems

When evaluating control systems for power plants, the GE Mark VI stands out against competitor systems. Several features contribute to its competitive edge, including redundancy, data processing speed, and advanced diagnostics.

● Redundancy: The GE Mark VI incorporates a robust redundancy design, ensuring that critical functions remain operational even during component failures. This feature significantly enhances reliability compared to many competitor systems.

● Data Processing Speed: It boasts superior data processing capabilities, allowing for real-time monitoring and quicker response times. This speed is crucial for optimizing plant performance and minimizing downtime.

● Diagnostics: Advanced diagnostic tools provide operators with detailed insights into system performance. This capability enables proactive maintenance, reducing the likelihood of unexpected failures.

Feature | GE Mark VI | Competitor Systems |

Redundancy | High redundancy for reliability | Varies, often lower |

Data Processing Speed | Faster processing for real-time data | Slower, leading to potential delays |

Diagnostics | Advanced tools for proactive maintenance | Basic diagnostics |

Unique Benefits of the GE Mark VI

The GE Mark VI offers several unique benefits that enhance overall performance. Key differentiators include its user-friendly interface, flexibility in integration, and comprehensive support services.

● User-Friendly Interface: Operators appreciate the intuitive design, which simplifies navigation and reduces training time. This ease of use translates into faster decision-making and improved plant operations.

● Flexibility: The system's ability to integrate with various third-party devices and legacy systems allows for tailored solutions that meet specific operational needs.

● Comprehensive Support: GE provides extensive support and resources, ensuring that operators have access to the latest updates and troubleshooting assistance.

Reducing Operational Risks

One of the standout features of the GE Mark VI is its ability to reduce operational risks compared to other systems. An analysis of failure rates and maintenance costs reveals significant advantages.

● Failure Rates: The GE Mark VI has a lower failure rate than many competing systems. This reliability means fewer unplanned outages and disruptions, which can be costly for power plants.

● Maintenance Costs: With its advanced diagnostics and predictive maintenance capabilities, the Mark VI helps identify issues before they escalate. This proactive approach leads to lower maintenance costs and less frequent repairs.

Comparison Metric | GE Mark VI | Competitor Systems |

Failure Rate | Lower than industry average | Higher, leading to more downtime |

Maintenance Costs | Reduced through predictive tools | Often higher due to reactive maintenance |

The GE Mark VI Control System not only excels in performance but also provides a range of competitive advantages that make it a top choice for power plants aiming for efficiency and reliability.

Conclusion

The GE Mark VI Control System offers significant benefits for power plants. It enhances efficiency and ensures operational reliability.

Upgrading to the GE Mark VI can lead to lower costs and improved performance.

In today’s energy sector, modern control systems like the GE Mark VI are essential for optimizing plant operations and integrating renewable energy sources.

FAQ

Q: What is the lifespan of the GE Mark VI Control System?

A: The GE Mark VI Control System typically has a lifespan of 15-20 years, depending on usage and maintenance.

Q: How easy is it to upgrade from older systems to the GE Mark VI?

A: Upgrading to the GE Mark VI is generally straightforward, with compatibility features for various legacy systems.

Q: What training is required for staff to operate the GE Mark VI?

A: Staff require training on the user interface and system features, which GE provides through comprehensive programs.

Q: Can the GE Mark VI be used in renewable energy applications?

A: Yes, the GE Mark VI effectively integrates with renewable energy sources, enhancing overall grid stability.

Q: What are the maintenance requirements for the GE Mark VI?

A: Maintenance includes regular system checks, software updates, and utilizing diagnostic tools for proactive management.