Are you curious about advanced control systems? The GE Mark VI stands out in turbine control technology.

This system enhances reliability and efficiency in industrial applications.

In this post, we’ll explore the key features of GE Mark VI and its significance in modern power generation.

Understanding GE Mark VI Control Systems

What is the GE Mark VI Control System?

The GE Mark VI Control System is a sophisticated platform designed for controlling industrial turbines. It primarily serves to enhance the efficiency and reliability of power generation processes. By integrating advanced technology, the GE Mark VI provides precise control over turbine operations, ensuring optimal performance.

Definition and Purpose

At its core, the GE Mark VI is a digital control system that manages various aspects of turbine operation. Its purpose is to monitor, control, and optimize turbine performance in real-time. This system helps operators respond swiftly to changing conditions, minimizing downtime and maximizing output.

Key Functions of GE Mark VI:

● Real-time monitoring of turbine parameters

● Automated control adjustments based on performance data

● Integration with other plant systems for comprehensive management

Historical Context and Evolution of the GE SPEEDTRONIC™ Series

The GE SPEEDTRONIC™ series has a rich history, evolving significantly since its inception. The Mark VI represents the latest advancement in this lineage, building on lessons learned from earlier models.

Model | Year Introduced | Key Features |

Mark I | 1980s | Basic control functions, analog technology |

Mark II | 1990s | Enhanced diagnostics, introduction of digital technology |

Mark V | Early 2000s | Advanced control algorithms, improved user interface |

Mark VI | 2005 | Full digital control, high-speed data processing, robust diagnostics |

The transition from analog to digital technology marked a significant milestone. Each iteration improved upon the last, leading to the sophisticated capabilities of the Mark VI.

Why is GE Mark VI Significant in Industrial Applications?

The significance of the GE Mark VI lies in its ability to transform how turbines are managed. In today's energy landscape, efficiency and reliability are paramount.

Benefits of Using GE Mark VI:

● Increased Reliability: The system's redundancy features ensure continuous operation, even in the event of a failure.

● Enhanced Efficiency: Real-time data processing allows for immediate adjustments, optimizing performance.

● Comprehensive Diagnostics: Built-in diagnostics help identify issues before they escalate, reducing maintenance costs.

In industrial applications, these features translate into lower operational costs and improved safety. The GE Mark VI not only meets the demands of modern power plants but also sets a standard for future control systems.

![GE Mark VI GE Mark VI]()

Core Features of GE Mark VI Control Systems

1. Flexible Redundant Control Architecture

Redundancy is crucial in control systems to ensure reliability and minimize downtime. The GE Mark VI offers several architectures, including Simplex, Dual Modular, and Triple Modular Redundant (TMR). Each architecture provides different levels of fault tolerance.

Benefits of TMR Architecture:

● Fault Tolerance: TMR allows the system to continue operating even if one module fails. This ensures uninterrupted service, which is vital in industrial settings.

● Continuous Operation: With TMR, the system can detect faults and switch to backup controls without any noticeable disruption.

Detailed Description of SIFT Technology: SIFT, or Software Implementation Fault Tolerance, enhances the reliability of the system further. It allows the software to handle faults gracefully, ensuring that operations remain stable.

Hardware Redundancy Details: The hardware components are also designed for redundancy. This includes multiple sensor interfaces and output mechanisms, which help maintain control even if one component fails.

Sensor Interface Configurations

The GE Mark VI employs advanced sensor configurations, such as:

● 3-Wire Servo Control: This setup ensures precise control of actuators, enhancing performance.

● 2-Out-of-3 Relay Logic: This logic system increases reliability by requiring agreement among multiple sensors before executing commands.

2. High-Speed Data Processing and Synchronization

The GE Mark VI excels in data processing capabilities. It supports high data throughput, which is essential for real-time control.

Maximum VME Rack Support: The system can handle multiple VME racks, enabling it to scale according to the needs of the plant.

Real-Time Feedback Control: Real-time feedback is critical for operational stability. The ability to process data quickly impacts overall efficiency, allowing for immediate adjustments to operations.

Role of IONet Network: IONet plays a vital role in synchronizing data between modules. This ensures that all components work seamlessly together, maintaining data integrity during operations.

High-Speed Data Interaction: Furthermore, the GE Mark VI allows high-speed data interaction with external systems, facilitating integration with other technologies and enhancing overall functionality.

3. Comprehensive Lifecycle Diagnostics and Maintenance

The GE Mark VI is equipped with extensive self-diagnostic features. These built-in capabilities provide real-time health monitoring, which is essential for maintaining system integrity.

Predictive Maintenance Advantages: By utilizing predictive maintenance strategies, the GE Mark VI can identify potential issues before they become significant problems. This reduces unplanned downtime and saves costs.

Examples of Fault Codes: The system generates specific fault codes that indicate various issues. Understanding these codes helps operators respond quickly to problems.

Maintenance Design Considerations: The design of the GE Mark VI includes hot-swappable components, allowing for easy replacement without shutting down the system. Remote diagnostics further enhance maintenance efficiency.

Compatibility with GE Diagnostic Tools: Integration with GE’s diagnostic tools helps streamline operations and reduce operational costs.

4. Broad System Integration and Compatibility

One of the standout features of the GE Mark VI is its compatibility across generations of GE systems. This cross-generational compatibility is especially beneficial for retrofitting older power plants, allowing them to utilize modern technology without complete overhauls.

Multi-Protocol and Multi-Device Interoperability: The system supports various protocols, including Modbus, Ethernet, and OPC. This flexibility enables seamless integration with third-party Distributed Control Systems (DCS) and monitoring systems.

Advantages of a Comprehensive Control Ecosystem: By integrating balance-of-plant (BOP) and power island control, the GE Mark VI creates a comprehensive control ecosystem. This integration enhances overall plant efficiency and simplifies management.

The GE Mark VI Control System stands out due to its innovative features, ensuring reliability, efficiency, and integration in modern industrial applications.

Key Products within the GE Mark VI Control System

Overview of Product Lineup

The GE Mark VI Control System features a modular design that allows for flexibility and scalability in various industrial applications. This modularity means that users can easily customize their systems to meet specific operational needs.

Key Components:

● Control Units: These are the brains of the system, responsible for processing data and executing control commands.

● I/O Terminal Boards: These boards facilitate communication between the control units and field devices, ensuring seamless data flow.

● Monitoring Modules: These modules provide real-time insights into system performance, allowing operators to make informed decisions.

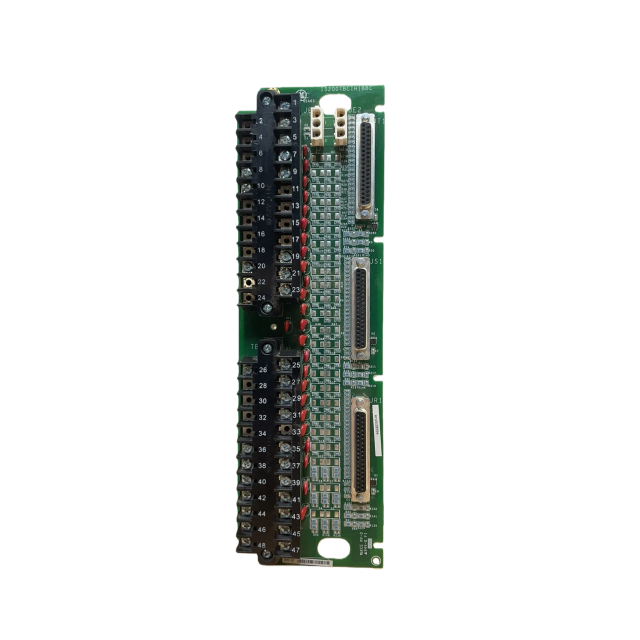

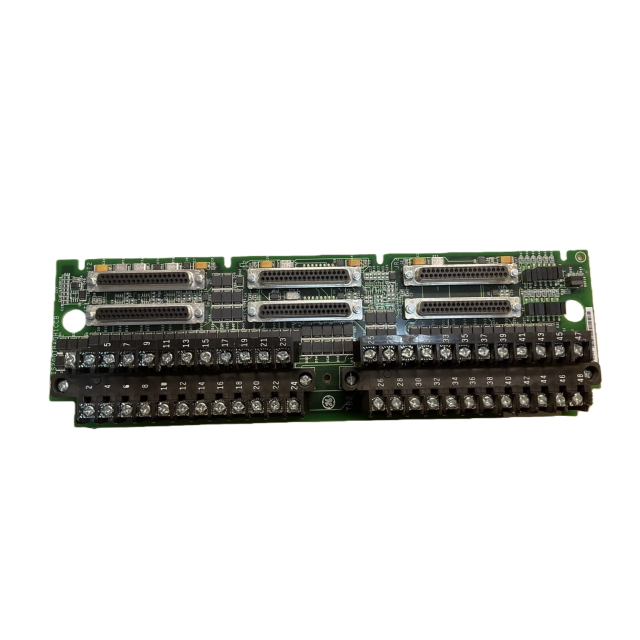

Highlighted Product Models: Among the notable models, the IS200TBCIH1BBC and IS200TBAIH1CDC stand out.

Product Model | Functionality | Key Features |

IS200TBCIH1BBC | Control unit for turbine applications | High-speed processing, fault tolerance |

IS200TBAIH1CDC | I/O terminal board | Supports multiple input/output types |

These products exemplify the advanced capabilities of the GE Mark VI system, providing essential functions that enhance overall operational efficiency.

Technical Specifications of GE Mark VI Products

Understanding the technical specifications of GE Mark VI products is crucial for ensuring optimal performance in diverse environments.

Environmental Adaptability: The GE Mark VI products are designed to operate effectively under varying conditions. Key specifications include:

● Temperature Ranges: They can function in temperatures ranging from -40°C to +70°C, making them suitable for both extreme cold and heat.

● Humidity Tolerance: These systems can handle humidity levels up to 95%, ensuring reliability in moist environments.

Installation and Power Supply Requirements: Installation methods are straightforward, allowing for quick deployment in the field.

● Power Supply Requirements: The products typically operate on a standard input voltage of 24V DC, ensuring compatibility with most power systems.

● Safety Features: Built-in protection mechanisms safeguard against overvoltage and short circuits, enhancing system reliability.

Input Voltage Specifications and Protection Mechanisms

The input voltage specifications are critical for ensuring the safety and efficiency of the GE Mark VI products.

● Input Voltage Range: Generally, these products accept a range of 18V to 30V DC, providing flexibility in power supply options.

● Protection Mechanisms: Each unit is equipped with features like surge protection and reverse polarity protection, which help prevent damage from electrical faults.

By combining advanced technology with robust specifications, GE Mark VI products are well-suited for demanding industrial environments. Their modular design and adaptability make them an ideal choice for modern power generation and control applications.

Competitive Landscape: GE Mark VI vs. Other Control Systems

Key Competitors in the Market

In the realm of industrial control systems, several key competitors challenge the GE Mark VI. Notable names include Siemens, Schneider Electric, and Honeywell. Each of these companies offers unique features that cater to various industrial needs.

Overview of Competitors:

● Siemens: Known for its SIMATIC series, Siemens focuses on a wide range of automation solutions, emphasizing integration and scalability.

● Schneider Electric: Their EcoStruxure platform provides robust IoT capabilities, enhancing connectivity and data management.

● Honeywell: With its Experion system, Honeywell emphasizes user-friendly interfaces and comprehensive process control.

Comparison of Redundancy and Fault Tolerance: When it comes to redundancy, GE Mark VI excels with its Triple Modular Redundant (TMR) architecture, which provides superior fault tolerance. In contrast, while Siemens also offers redundancy features, they may not match the same level of resilience found in GE systems.

Feature | GE Mark VI | Siemens SIMATIC | Schneider EcoStruxure | Honeywell Experion |

Redundancy Type | TMR | Dual Redundant | Modular Redundant | Dual Redundant |

Fault Tolerance Level | High | Moderate | Moderate | High |

Diagnostic Capabilities | Advanced | Standard | Advanced | Comprehensive |

Lifecycle Support and Maintenance Costs: Lifecycle support is another critical area. GE Mark VI generally offers robust support, but competitors like Schneider Electric provide competitive maintenance packages that can lower long-term costs. Thus, organizations must weigh initial investment against future expenses.

Strengths and Weaknesses of GE Mark VI

The GE Mark VI boasts several strengths that make it a preferred choice in many industrial settings. One of its most significant advantages is reliability. The TMR architecture ensures that even if one component fails, the system continues to operate smoothly.

Key Advantages:

● Flexibility: The modular design allows for easy upgrades and customization, adapting to changing operational demands.

● Lifecycle Support: GE provides extensive support throughout the product lifecycle, ensuring that users can maintain optimal performance over time.

Potential Limitations: However, there are some challenges associated with the GE Mark VI. The initial costs can be higher compared to some competitors, which may deter smaller organizations.

Cost Considerations:

● Initial Costs: Investment in GE Mark VI systems can be substantial.

● Long-Term Operational Efficiency: Despite higher upfront costs, many users find that the efficiency and reliability of GE systems lead to lower operational costs over time.

In conclusion, while the GE Mark VI offers significant advantages in reliability and support, potential buyers should consider both initial and long-term costs when evaluating their options against competitors. This balanced approach will help organizations make informed decisions that align with their operational goals.

![GE Mark VI GE Mark VI]()

Real-World Applications of GE Mark VI Control Systems

Industries Utilizing GE Mark VI

The GE Mark VI control system finds extensive application across various industries, demonstrating its versatility and reliability. Key sectors benefiting from this advanced control system include power generation, oil and gas, and a range of industrial applications.

Overview of Sectors:

● Power Generation: GE Mark VI is widely used in both gas and steam turbine applications, enhancing efficiency and performance.

● Oil and Gas: In this sector, it controls critical processes, ensuring safety and operational integrity.

● Industrial Applications: Many manufacturing facilities leverage GE Mark VI for automation and process control, optimizing production lines.

Successful Implementations: Real-world case studies highlight the effectiveness of GE Mark VI. For example, in large combined cycle power plants, the system manages complex operations, ensuring optimal performance and energy efficiency.

Industry | Application | Outcome |

Power Generation | Combined Cycle Power Plants | Increased efficiency by 10% |

Oil and Gas | Pipeline Monitoring and Control | Enhanced safety and reduced downtime |

Industrial Manufacturing | Automated Production Lines | Improved productivity by 15% |

In the oil and gas sector, GE Mark VI has been crucial in managing critical turbines, where reliability is essential. These implementations demonstrate how the system can adapt to specific industry needs, providing tailored solutions that drive operational success.

Future Trends in Control Systems

As industries evolve, so do the technologies that support them. Emerging technologies in turbine control are shaping the future landscape, and GE Mark VI is at the forefront of these developments.

Emerging Technologies: Innovations such as advanced data analytics and machine learning are becoming integral to turbine control systems. These technologies enable predictive maintenance and real-time performance monitoring, significantly enhancing operational efficiency.

Role of GE Mark VI: The GE Mark VI control system is designed to adapt to these future industry needs. Regular software updates ensure that users benefit from the latest advancements, maintaining competitiveness in a rapidly changing market.

Discussion on Enhancements: With ongoing system enhancements, GE Mark VI continues to evolve. These updates not only improve functionality but also integrate new features that align with industry trends, ensuring users are equipped to face future challenges effectively.

In summary, the GE Mark VI control system is a key player in various industries, providing reliable solutions and adapting to future technological advancements.

Conclusion

The GE Mark VI control system offers advanced features, including reliability and flexibility. Its applications span power generation, oil and gas, and industrial sectors. Choosing the right control system is crucial for operational efficiency.

Consider the benefits of GE Mark VI as you explore your options. Delve deeper into its capabilities to see how it can enhance your operations.