When it comes to protecting critical rotating machinery, few names carry as much weight as Bently Nevada. Its 3500 Series has become the global standard for vibration monitoring and machine protection, trusted by refineries, power plants, and process industries around the world. Designed to meet stringent API 670 requirements, the 3500 platform continuously tracks vibration, position, and speed—helping operators detect faults before they become failures.

Explore available modules here: Bently Nevada 3500 Products at JoyyParts

Key Takeaways

The Bently Nevada 3500 system is a rack-based machine protection system with modular monitors, relays, and communication interfaces.

It provides continuous monitoring for turbines, compressors, pumps, and other rotating machinery.

Fully scalable—from a single-train installation to a multi-machine plant network.

Integrates easily with DCS, PLC, or historian systems for centralized monitoring and shutdown logic.

Factors to Consider When Selecting a Vibration Monitoring System

| Factor | Importance (%) |

|---|

| Measurement functionality & API compliance | 12.0 |

| Signal chain & diagnostics | 10.5 |

| Integration with DCS/PLC systems | 9.8 |

| Rack and module scalability | 8.5 |

| Reliability & redundancy | 10.8 |

| Service and support | 10.0 |

| Initial cost | 9.2 |

| Training & documentation | 4.8 |

| Lifecycle and obsolescence management | 6.4 |

| Ongoing maintenance cost | 4.0 |

Performance, scalability, reliability, and ease of integration dominate user priorities when choosing a vibration monitoring platform.

Bently Nevada 3500 System Architecture

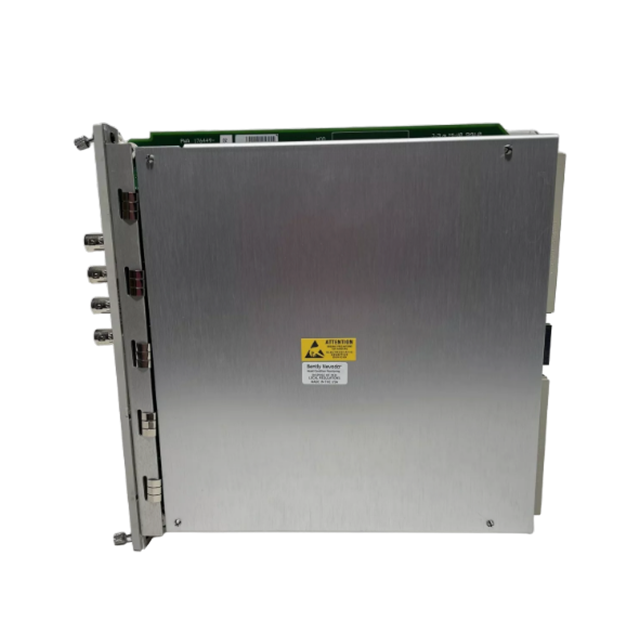

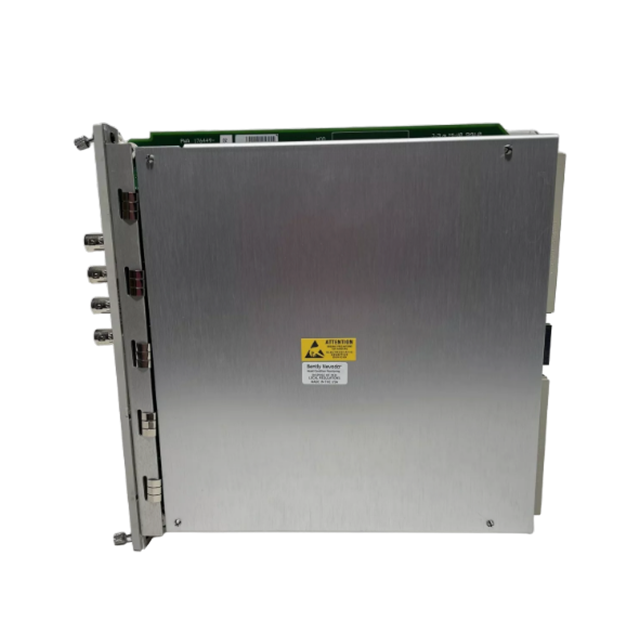

The 3500 system follows a modular design. At its core sits a 19-inch rack housing the power supplies, interface modules, and a series of monitor cards.

Rack & Power Supply: Holds up to 14 monitoring slots with dual-redundant AC/DC power options.

Transient Data Interface (TDI) or Rack Interface Module (RIM): Manages configuration, communications, and transient data capture.

Monitor Modules: Accept sensor inputs (vibration, position, temperature, speed).

Relays: Execute alarm and trip logic.

Communication Modules: Provide Modbus RTU/TCP and OPC outputs for system integration.

Signal flow is simple but powerful: sensor → monitor → alarm logic → relay output → DCS/historian.

Core Modules and Functions

See full catalog: Bently Nevada 3500 at JoyyParts

Performance and Diagnostics

Each monitor card provides real-time processing with OK, Alert, and Danger states. Built-in diagnostics check transducer health, bias voltage, and wiring conditions. This ensures faults such as open or short circuits are detected instantly.

Alarm logic can be tailored per channel with programmable delays and voting.

Tip: Proper alarm configuration avoids nuisance trips and ensures true protective action during vibration excursions.

Integration with Control and Information Systems

Bently Nevada 3500 communicates seamlessly with existing plant automation networks.

To DCS/PLC/SCADA: via 3500/22M (Modbus RTU/TCP) or TDI (OPC DA).

To historians: Trend and event data for long-term analysis.

Retrofit capabilities: Supports migrations from older 3300 or 7200 series.

Security: Segregated protection and monitoring networks to meet modern cybersecurity standards.

System Reliability, Flexibility, and Lifecycle Value

The Bently Nevada 3500 Series is built on a foundation of reliability and long-term operational confidence. Every component—from redundant power supplies to the fault-tolerant backplane—has been engineered to minimize single points of failure and ensure continuous machinery protection. Relay modules use 1oo2 and 2oo3 voting logic, meeting API 670 and IEC standards, to prevent false trips while maintaining safety integrity during genuine vibration events.

Beyond reliability, the 3500 platform offers exceptional flexibility and scalability. Plants can start with a single rack for one critical machine and expand to multi-train systems without redesign. Spare slots and remote I/O panels allow cost-effective additions as asset counts grow, ensuring smooth scalability from pumps and fans to large turbine trains.

Integration with existing plant systems is equally seamless. The 3500 communicates via Modbus and OPC with leading DCS and PLC platforms, supporting open connectivity and data sharing across the enterprise. Its compatibility with Proximitor®, seismic, and velocity sensors enables engineers to design hybrid systems that blend new and legacy instrumentation without compatibility issues.

Operationally, configuration and daily use are straightforward. Engineers can easily define sensor types, ranges, and alarm setpoints using Bently Nevada’s configuration software. Real-time vibration and position data are displayed through intuitive interfaces, with color-coded alarm banners for quick diagnostics. Built-in bias voltage and gap checks simplify commissioning, saving time and reducing setup errors.

While the 3500 represents a premium investment, its modular and upgradable design delivers superior lifecycle value. Instead of full system replacements, users can modernize individual modules as technology evolves. Through JoyyParts, operators have access to genuine Bently Nevada parts, firmware updates, and legacy support, ensuring system longevity for decades of reliable operation.

Common Applications

Turbine Trains – Gas, steam, and hydro turbines for power generation use the 3500 for radial/axial vibration, thrust position, and overspeed protection.

Centrifugal Compressors – Monitor journal bearing vibration and surge events using multi-Keyphasor inputs.

Pumps, Fans, Blowers, Generators – Detect unbalance, misalignment, or looseness to prevent unscheduled stops.

| Asset | Primary Measurements | Typical Modules |

|---|

| Gas/Steam Turbine | Radial / Axial Vibration, Thrust, Speed | 3500/40M, 3500/42M, 3500/25, 3500/32M |

| Centrifugal Compressor | Vibration, Phase, Temperature | 3500/42M, 3500/60, 3500/22M |

| Pump/Fan/Blower | Overall Vibration, Temperature | 3500/40M, 3500/61 |

| Hydro Turbine | Shaft Vibration and Position | 3500/46M, 3500/50M |

Featured Bently Nevada 3500 Modules on JoyyParts

3500 Racks & Power Supplies

3500/20 TDI and 3500/22M Communications Modules

3500/25 Keyphasor® Module

3500/40M and 3500/42M Vibration Monitors

3500/32M and 3500/33 Relay Modules

Request a quotation or technical consultation: JoyyParts – Bently Nevada 3500 Series

Frequently Asked Questions

Q1. What is the Bently Nevada 3500 system used for?

The Bently Nevada 3500 system is a vibration monitoring and machine protection platform designed for critical rotating equipment such as turbines, compressors, and pumps. It continuously monitors vibration, temperature, and speed, providing early warning of mechanical issues and triggering protective shutdowns when necessary.

Q2. How does the Bently Nevada 3500 system work?

The 3500 system uses sensors (Proximitor®, seismic, and velocity probes) connected to monitor modules that analyze machine vibration and position data. When the system detects abnormal conditions, it sends alarms to the DCS or activates relay outputs to safely shut down the machine before damage occurs.

Q3. What is the difference between vibration monitoring and machine protection?

Vibration monitoring focuses on collecting and trending data for condition analysis, while machine protection provides real-time shutdown logic to prevent failures. The Bently Nevada 3500 combines both functions—continuous monitoring and protection logic—in one integrated rack system.

Q4. What are the main components of the Bently Nevada 3500 system?

A typical 3500 system includes:

Rack and power supplies (AC/DC, redundant)

Transient Data Interface (TDI) or Rack Interface Module (RIM)

Vibration, position, and temperature monitors

Keyphasor® modules for phase and speed reference

Relay modules for alarm and trip logic

Communication interfaces (Modbus, OPC)

See all modules here: Bently Nevada 3500 Series at JoyyParts

Q5. What makes the 3500 Series reliable for critical machines?

The 3500 features redundant power supplies, a fault-tolerant backplane, and 1oo2 / 2oo3 relay voting logic that prevents false trips. All modules meet API 670 and IEC 61508 safety standards for industrial machinery protection.

Q6. Can the Bently Nevada 3500 integrate with my existing DCS or PLC system?

Yes. The system communicates via Modbus RTU/TCP and OPC DA using the 3500/22M or 3500/20 TDI modules. This allows direct integration with DCS, PLC, and historian systems for seamless data exchange and centralized alarm management.

Q7. What industries commonly use Bently Nevada 3500 systems?

The 3500 is widely used in:

Oil & Gas (upstream, midstream, downstream)

Power Generation (steam, gas, and hydro turbines)

Chemical and Petrochemical plants

Refining and Fertilizer manufacturing

Pulp and Paper industries

Water and wastewater facilities

Q8. How do I configure or calibrate a Bently Nevada 3500 system?

Configuration is done through Bently Nevada’s Configuration Software. Engineers define each channel’s sensor type, range, and alarm setpoints, then validate bias voltages and gaps during commissioning. Regular calibration ensures accurate vibration and speed measurement.

Q9. What is the lifespan of a Bently Nevada 3500 system?

With proper maintenance, the 3500 can operate reliably for over 15–20 years. Its modular design allows incremental upgrades of monitors and communication modules without replacing the entire rack—extending lifecycle value and lowering total ownership cost.

Q10. How is the 3500 Series different from the older 3300 or 7200 systems?

The 3500 provides:

Faster processing and higher accuracy

Modular digital architecture

Improved diagnostics and integration

OPC/Modbus communication support

Easier configuration and alarm management

It’s a direct migration path for users of legacy Bently Nevada systems.

Q11. What types of sensors are compatible with the Bently Nevada 3500?

The system supports Proximitor® proximity probes, velocity transducers, accelerometers, and Keyphasor® speed sensors, as well as RTD and thermocouple inputs for temperature monitoring. These can be combined in mixed configurations within the same rack.

Q12. How does the system detect vibration problems early?

The 3500’s monitors continuously evaluate vibration amplitude, phase, and frequency trends. When these exceed configured alarm thresholds, the system triggers an alert or danger state, giving maintenance teams time to act before equipment failure.

Q13. Can the 3500 be used for predictive maintenance programs?

Yes. The 3500 can export real-time and historical vibration data to plant historians and predictive maintenance platforms. This allows reliability engineers to perform trend analysis, FFT diagnostics, and root-cause investigation.

Q14. What kind of support does JoyyParts provide for Bently Nevada systems?

JoyyParts supplies original Bently Nevada 3500 modules, provides compatibility consultation, legacy system upgrades, and global shipping. We also help clients match replacement parts for obsolete configurations and maintain full lifecycle support.

Explore now: Bently Nevada 3500 Modules – JoyyParts

Q15. Is the Bently Nevada 3500 Series compliant with API 670?

Yes. The 3500 Series fully complies with API 670 (Machinery Protection Systems), the industry benchmark for turbomachinery vibration and overspeed protection.

Q16. How can I tell if my Bently Nevada 3500 module is genuine?

Each genuine Bently Nevada module carries a unique serial code and GE/Baker Hughes mark. Always purchase from verified suppliers like JoyyParts, which provides warranty and authenticity verification for every shipment.

Q17. What happens if one module fails in the rack?

If a module fails, the 3500’s backplane redundancy allows the system to continue operating. Fault LEDs and diagnostics identify the failed card, which can be hot-swapped to minimize downtime.

Q18. How much does a full 3500 system cost?

Costs vary depending on the configuration, number of channels, and sensors. A basic system for one turbine can start around $10,000–$20,000, while full multi-train protection setups can exceed $100,000.

JoyyParts can provide a customized quotation based on your exact requirements.

Q19. What software tools are used with the 3500 system?

The system uses Bently Nevada’s Configuration and Monitoring Software suite. It enables engineers to set up channels, perform diagnostics, and export data to external systems. It also supports remote configuration and event capture through the TDI module.

Q20. Can the 3500 system work in hazardous or explosive environments?

Yes. When installed with appropriate enclosures and certified components, the 3500 can operate in Class I, Division 2 / Zone 2 hazardous areas, meeting relevant ATEX and IECEx certifications.

Conclusion

The Bently Nevada 3500 Series remains the industry benchmark for vibration monitoring and machine protection. Its modular architecture, robust reliability, and broad integration options make it ideal for any critical rotating asset. By partnering with JoyyParts, you gain access to genuine Bently Nevada modules, global shipping, and expert technical support to keep your plant safe and efficient.

Explore the full range now: Bently Nevada 3500 at JoyyParts