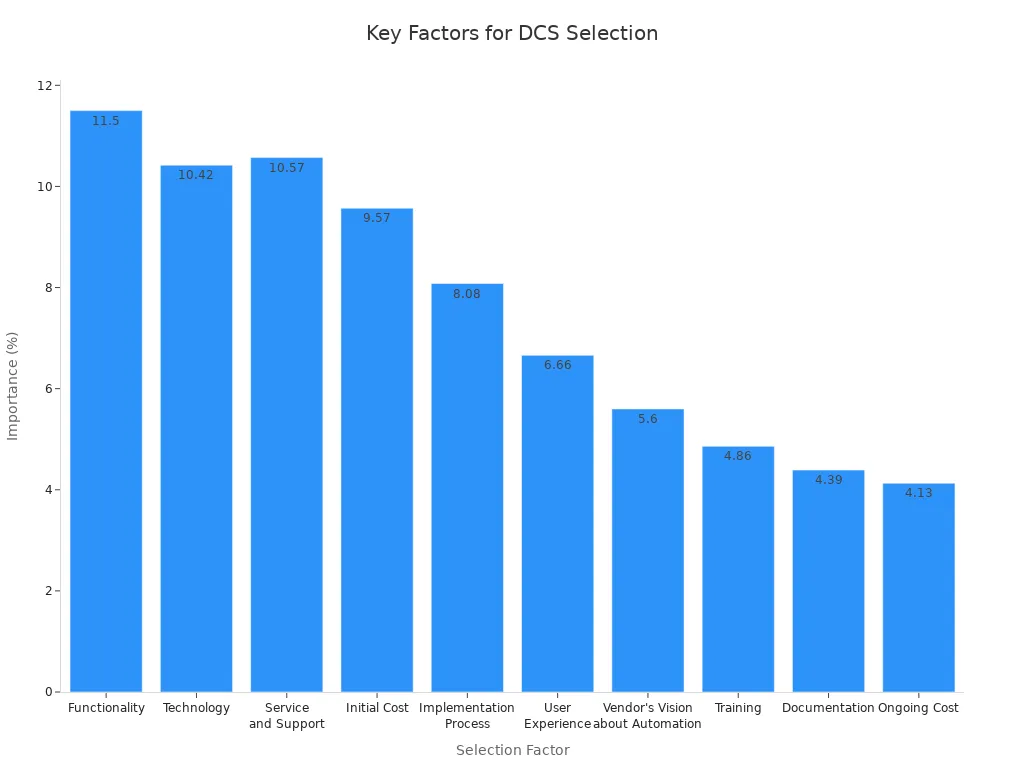

When you pick a distributed control system for factories, you see two top choices: honeywell dcs and ABB. New market numbers show honeywell dcs has 19% of the market. ABB has a new system that can fit many types of businesses. You should think about some important things before you choose. Here are the most important ones:

Factor | Importance (%) |

Functionality | 11.50 |

Technology | 10.42 |

Implementation Process | 8.08 |

User Experience | 6.66 |

Vendor's Vision about Automation | 5.60 |

Service and Support | 10.57 |

Initial Cost | 9.57 |

Training | 4.86 |

Documentation | 4.39 |

Ongoing Cost | 4.13 |

Performance, how things work together, trust, growth, and how easy it is to use are very important. What you need will help you choose the best dcs for your factory automation.

Key Takeaways

Think about how the system works and its technology first. These things affect how well your automation runs.

Look at how each system connects with others. Honeywell DCS works best with other Honeywell products. ABB DCS can work with many different brands.

Check how easy the system is to use and what help you can get. Honeywell has an easy-to-use interface. ABB has lots of help from its community and resources.

Think about both starting and future costs. Both systems cost a lot at first. They help you save money later because they are reliable and work well.

Pick a system that fits your industry needs. Honeywell is great for places where safety is very important. ABB works well for many kinds of manufacturing jobs.

DCS Comparison

When you pick a distributed control system, you want it to fit your needs. Honeywell Experion PKS C300 and ABB 800xA are both strong choices for industrial automation. You can use the table below to see their main features side by side.

Feature | Honeywell Experion PKS C300 | ABB 800xA |

Performance | High-speed processor, minimal latency in communication | Focus on reducing total cost of ownership and increasing productivity |

Scalability | Designed to be scalable for various process sizes | Supports evolution of installed base to current offerings |

Integration | Seamless integration with Honeywell’s environment | Integrates with various systems, enhancing flexibility |

Reliability | Redundancy in hardware and communication | Emphasizes risk reduction and enhancing security |

User Preference | 80% recommendation rate | 86% recommendation rate, strong global market share |

Cost | Premium-priced, cost-effective upgrades available | Premium-priced, focus on long-term savings |

Performance Comparison

You want your distributed control system to work well every day. Honeywell Experion PKS C300 uses a fast processor. This means you get quick responses and little delay. It helps your operations run smoothly. The system is built to lower downtime and save money over time.

ABB 800xA tries to help you work faster and spend less. Many people like how it helps them get more from their automation. ABB’s system is good for companies that want to upgrade without starting over.

Tip: If you need a distributed control system that handles lots of data fast, both choices work well. Look at your own process needs to pick the best one.

Integration Overview

Integration is important when you choose a distributed control system. Honeywell Experion PKS C300 connects easily with other Honeywell products. You can link it to your current Honeywell setup. This makes upgrades and changes simple and saves money. The system also has strong security to keep your data safe.

ABB 800xA connects with many different systems. You can use it with other brands, which gives you more options. ABB also helps you move from older Honeywell systems, so switching or upgrading is easier.

Honeywell distributed control system has strong security to stop cyber threats and protect your data.

ABB 800xA also has advanced security, like Honeywell Forge, to keep your operations safe.

Think about how each system fits with what you already have. If you want easy connection with Honeywell products, Experion PKS C300 is a good pick. If you need to connect with many types of technology, ABB 800xA gives you that choice.

Note: Both distributed control system solutions help you manage your process and improve automation. Your choice depends on what you have now and what you want in the future.

Honeywell DCS Performance

![Honeywell DCS or ABB DCS Making the Right Choice for Industrial Automation]()

Reliability

You want your automation system to work well every day. The honeywell dcs, like the Experion PKS C300, is very reliable. This system uses new technology to keep things safe and steady. The C300 has strong reliability because it has built-in cybersecurity, backup hardware, and good diagnostics. These things help stop downtime and keep your plant working. The table below shows how the C300 focuses on control and data collection. This helps it be more reliable than some other systems.

Feature | Honeywell Experion PKS C300 | ABB 800xA |

Core Functionality | Control and data acquisition for process control | Communication with HART-enabled devices |

Performance Focus | Enhances process control performance and reliability | Collects, configures, calibrates, and diagnoses HART devices |

Speed and Response

You need your plant to react fast and give correct answers. The C300 has a fast processor for real-time checks and quick feedback. You can see what is happening right away and make changes fast. The control software always gives the same results. You also get advanced ways to talk to other systems, like Ethernet IP and OPC UA. These help your system react quickly when things change.

Tip: Watching your system in real time helps you find problems early and fix them fast.

Scalability

When your business gets bigger, your dcs should grow too. The honeywell dcs is flexible and can get bigger as needed. Its design lets you add or upgrade parts without stopping your plant. You can start small and add more later. The C300 works with universal I/O and remote setup, so it fits many types of plants. This makes it easy to use for new projects or upgrades. You get a system that changes with your needs and helps you grow.

The C300 is also great for keeping your system safe. It has a built-in firewall, device lists, and security locks. These tools keep your data safe and protect your plant from threats.

Integration Capabilities

Third-Party Integration

You want your distributed control system to work with many products. Honeywell DCS and ABB 800xA can connect with third-party platforms. You can link devices from different vendors and control them together. This makes your plant flexible and stops you from using just one brand. ABB 800xA is helpful if you want to move from a Honeywell system. ABB gives you a clear way to switch from Honeywell TDC3000 or Experion to ABB 800xA. This helps you keep your plant running while you upgrade.

Infrastructure Compatibility

Your system should fit with what you already have. Honeywell DCS works well with old Honeywell equipment. You can upgrade without changing everything. The Honeywell Controledge UOC Controller lets you use ControlLogix I/O and keep your controls and HMI. This saves money and keeps downtime low. ABB 800xA also connects with many types of equipment. You can use it with new and old machines. This helps you control your plant and grow your automation over time.

Standards Support

Automation systems need to follow industry standards for good integration. Honeywell and ABB both support OPC UA. This standard lets you connect devices and apps from different brands. You get safe and reliable data sharing in your plant. Both companies join the Open Process Automation Forum. This group helps systems from different suppliers work together. Using these standards gives you more ways to grow and change your plant.

Tip: Pick a distributed control system that supports strong standards. This gives you more freedom to grow and change your plant later.

User Experience

Interface

How you use a control system is very important. You want it to be simple and easy to learn. Many people say Honeywell Experion PKS is easy to use. Its design helps new operators learn faster. This means you can start working sooner. ABB Ability System 800xA has many features. Some people think its interface is hard to use. You might need extra training to use all the tools.

System | Interface Quality | Ease of Use |

Honeywell Experion PKS | User-Friendly Interface | Simplifies operator training |

ABB Ability System 800xA | Complex with a steep learning curve | Requires significant training |

The table shows Honeywell Experion PKS is simple for users. ABB 800xA gives you more choices, but it takes longer to learn. Reviews show 86% of ABB users would tell others to use it. For Honeywell, 80% of users would recommend it. Both systems have many happy users.

Support

Good support helps you fix problems and learn new things. Honeywell and ABB both give strong support for their DCS. You can get help from experts or other users. ABB has a Control Systems community for sharing ideas. You can watch videos and tutorials on their YouTube channel. LinkedIn groups let you talk to ABB experts and users.

ABB Control Systems community for sharing ideas and solutions

YouTube channel with tutorials and presentations about ABB control systems

LinkedIn groups for System 800xA, Freelance DCS experts, and Symphony Plus users

Honeywell DCS users also get help from a global support team. You can ask Honeywell experts for help with setup or upgrades. Both companies want you to use your DCS well.

DCS Cost

Initial Cost

When you look at DCS solutions, you see that Honeywell and ABB use advanced technology. These DCS vendors make their systems work fast and grow with your needs. You should know that both Honeywell Experion PKS C300 and ABB 800xA cost more at first. Both systems use top hardware and software. This means you pay more at the start than for brands like Delta-V or Foxboro. The higher price is because of strong security and powerful control features in each system.

DCS Vendor | Initial Cost Level | Notable Features |

Honeywell | High | Advanced security, easy upgrades |

ABB | High | Flexible migration, strong support |

Note: You pay more at first, but you get strong systems that can handle tough jobs.

Maintenance

After you set up your DCS, you need to think about keeping it working. Honeywell and ABB both have support plans to help you. You might pay for updates, new parts, and help from experts. These costs can add up, but they stop bigger problems later. Honeywell lets you upgrade parts without changing the whole system. ABB also lets you upgrade slowly, so you can control costs. Both systems care about safety and trust, so your automation works well.

Updates keep your system up to date.

Support teams help you fix problems fast.

Upgrades help your system grow as your business grows.

You pay more for these DCS systems, but you get good performance and less worry. If you want a system that lasts and can change, the higher cost can be worth it.

Use Cases

Honeywell DCS Scenarios

You want a control system that works for your industry. Honeywell DCS is best where safety and reliability are very important. You see it in power plants and oil and gas fields. It is also used in chemical factories. The system helps you handle tough jobs and keeps things running well. If you need to connect with old equipment, Honeywell DCS lets you upgrade without spending too much. You can use it in many places, like manufacturing and food and beverage.

Here is a table that shows where Honeywell DCS is used most:

Industry | Description |

Oil & Gas | Used in extraction and processing |

Refining | Essential for refining operations |

Power Generation | Manages power plants |

Chemicals | Applied in chemical production |

Manufacturing | Used in various processes |

You also find Honeywell DCS in these areas:

Pharmaceuticals

Specialty Manufacturing

Biotech

Food & Beverage

If you work in a place where safety matters or need to link many systems, Honeywell DCS helps you do your job. You get strong security and easy ways to connect your automation.

Tip: Pick Honeywell DCS if you want safe control and simple upgrades in industries with strict safety rules.

ABB DCS Scenarios

You may want a system that is a leader and works for many factories. ABB DCS is known for its long history and strong technology. You see ABB DCS in manufacturing, chemicals, oil and gas, and power plants. It also works well in pharmaceuticals and biotech. ABB DCS helps you move from old systems, even Honeywell, without stopping your work.

You can use ABB DCS for these jobs:

Manufacturing

Chemicals

Oil and Gas

Power Generation

Pharmaceuticals

Biotechnology

ABB is a leader in automation, so you get steady power and better sustainability. You can add renewable energy and keep your plant working well. If you want a flexible interface and good support, ABB DCS is a good choice.

Note: Choose ABB DCS if you want top technology and easy upgrades from old systems. You get strong connections and support for modern automation.

You have lots of choices when picking a DCS. The table below shows the main differences to help you pick:

Feature | Honeywell DCS | ABB DCS |

Modularity | Custom solutions that change as your needs grow | One system that brings all functions together |

Reliability | Network fixes itself to keep things running | Extra parts and smart design stop failures |

Integration Capabilities | Works easily with equipment from many brands | Smooth workflow helps stop mistakes |

To choose well, you should:

Look at what you use now and what you will need later.

Think about quality, speed, and how much it costs.

Make sure you can grow and get good help from the company.

Having a good plan and learning how to use the system helps you avoid problems and do well for a long time.

FAQ

What is a distributed control system (DCS)?

A distributed control system helps you run big machines. It lets you watch equipment and collect data. You can make fast choices with it. This system makes your plant safer and keeps things working well.

How do you choose between Honeywell and ABB for automation?

You need to think about what your plant needs. Look at how reliable each system is. Check if it works with your other equipment. See what kind of help you get. Honeywell is good for safety and simple upgrades. ABB is better if you want more options and easy changes. Pick the one that matches your goals.

Can you upgrade your old system to a new DCS?

Yes, you can change your old system to a new one. Honeywell and ABB both help you move to new technology. You can keep your plant working while you upgrade your controls.

What support do you get after installing a control system?

You get help from experts who answer questions and fix problems. There are online guides and training to help you learn. You can join groups to talk with other users. This support helps you use your system every day.