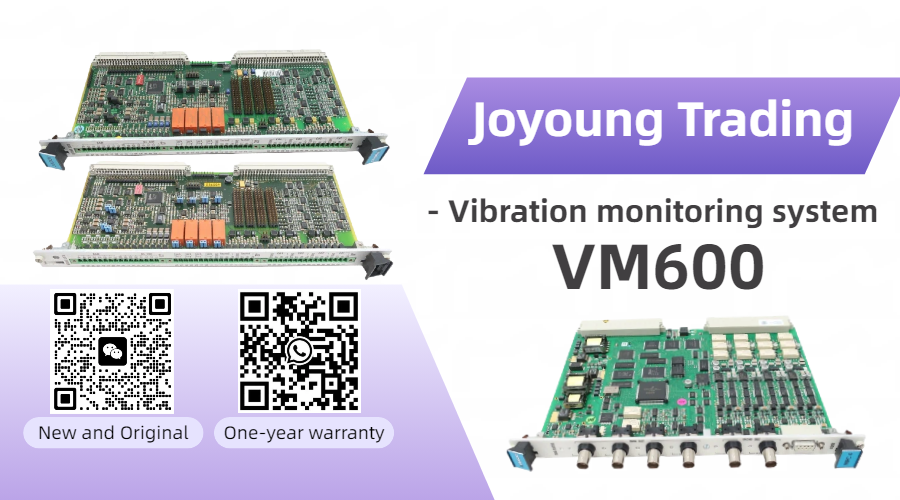

VM600 Series Product Introduction

The VM600 Series stands as a high-performance, integrated machine condition monitoring and protection system, engineered to deliver real-time oversight of

rotating machinery and critical industrial equipment. Designed for reliability in harsh operational environments, it combines multi-channel data acquisition,

intelligent fault diagnosis, and modular scalability to meet the demands of diverse industrial scenarios.

〖Core Product Features〗

Modular Hardware Architecture

The system adopts a flexible modular design, including core units such as communication gateways, machine protection modules, relay output modules, and

power supply modules. All modules support hot-swappable installation, enabling on-site maintenance without interrupting equipment operation. The compact

19-inch rack-mounted structure is suitable for both centralized control rooms and distributed on-site monitoring stations, with strong compatibility for

expansion (up to 16-channel signal input per module).

Comprehensive Condition Monitoring Capabilities

It supports multi-parameter detection covering vibration, displacement, speed, temperature, and dynamic pressure. The built-in high-precision signal

conditioning circuit ensures accurate collection of raw data, with a frequency response range of 0.1Hz–8kHz, fully adapting to the monitoring needs of low-

speed rotating equipment (such as water turbines) and high-speed precision machinery (such as gas turbines). The system integrates automatic fault grading

functions based on international standards, which can issue early warning and shutdown signals in real time according to preset thresholds, effectively

preventing unplanned equipment downtime.

Intelligent Data Analysis & Management

Equipped with dedicated configuration and analysis software, the system realizes functions such as real-time data display, historical trend query, FFT spectrum

analysis, and order tracking. It supports gigabit Ethernet communication and can seamlessly connect to upper-level SCADA or MES systems, realizing unified

management of equipment operation data. The built-in data storage module can retain monitoring records for more than 12 months, providing a reliable data

basis for predictive maintenance and equipment life cycle management.

Rugged & Reliable Design

With a wide operating temperature range of -55°C to 90°C and IP68-rated sensor interfaces, the system can operate stably in extreme environments such as

high temperature, high humidity, and strong electromagnetic interference. It complies with international industry standards such as ISO 10816 and API 670, and

has obtained multiple certifications including CE and explosion-proof certification, meeting the safety requirements of hazardous areas in petrochemical and

other industries.

IOC4T 200-560-000-016 Input/output card

The IOC4T 200-560-000-016 Input/Output Card is a high-performance, dedicated interface module designed for integration with the VM600 Series machine

condition monitoring and protection system, serving as a critical component for signal acquisition, control logic execution, and alarm output in industrial

rotating machinery applications. It features a versatile channel configuration, including 4 dynamic analog input channels (±10V DC/AC) compatible with

proximity probes, accelerometers, and RTDs for capturing vibration, displacement, speed, and temperature signals, 2 dedicated tachometer inputs (0.1Hz–

10kHz) supporting magnetic pickup and TTL signals for speed measurement and phase reference, 8 Form C relay outputs (250V AC/30V DC, 5A) for alarm and

emergency shutdown control, and 32 programmable open-collector outputs (jumper-selectable) for auxiliary control tasks. Equipped with 4 built-in DACs (0–

10V) and 4 voltage-current converters (4–20mA, jumper-selectable), the card enables calibrated analog signal output for seamless integration with upper-level

control systems. Onboard anti-interference circuits and electrical isolation technology ensure stable signal processing even in harsh industrial environments with

strong electromagnetic interference, while the hot-swappable design allows for on-site maintenance without interrupting system operation. Compliant with

international industry standards and compatible with the VM600 Series’ modular architecture, this input/output card is widely used in power generation,

petrochemical, aerospace, and general manufacturing sectors to support real-time equipment status monitoring, fault early warning, and predictive

maintenance strategies.

IOC4T 200-560-000-019 Input/Output Card

The IOC4T 200-560-000-019 Input/Output Card is a key modular interface component tailored for the VM600 Series machine condition monitoring and

protection system, boasting versatile I/O configurations including 4 dynamic analog input channels for vibration, displacement and temperature signals, 2

dedicated tachometer inputs for speed measurement, 8 Form C relay outputs for alarm and shutdown control, and 32 programmable open-collector outputs for

auxiliary tasks. It also integrates 4 built-in DACs and 4 voltage-current converters (4–20mA) to enable smooth signal transmission to upper-level systems, with

onboard anti-interference circuits ensuring stable performance in harsh industrial environments; its hot-swappable design allows for on-site maintenance

without disrupting system operation, making it ideal for real-time equipment monitoring applications across power generation, petrochemical and general

manufacturing sectors.

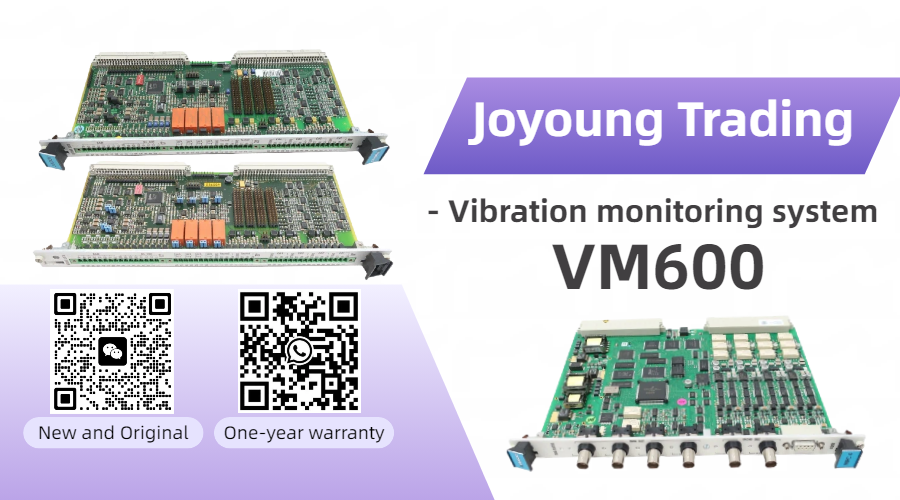

MPC4 200-510-078-115 Machinery Protection Card

The MPC4 200-510-078-115 Machinery Protection Card is a core component of the VM600 Series monitoring and protection system, designed to provide real-

time oversight and safety for critical rotating machinery. It features 4 fully programmable dynamic signal inputs that accept acceleration, velocity, displacement,

and dynamic pressure signals, plus 2 dedicated tachometer inputs compatible with proximity probes, magnetic pickups, and TTL signals to support speed

measurement and phase reference. Equipped with advanced on-board digital processing capabilities, including filtering, integration/differentiation, order

tracking, and multi-parameter calculation (such as eccentricity, thrust position, and housing expansion), the card enables precise equipment condition

assessment. Users can program alert and danger set points with adjustable time delays, hysteresis, and latching functions, which can be adapted to speed or

external signals for flexible protection. It integrates a built-in "OK system" for continuous sensor and signal chain monitoring, with front-panel LEDs indicating

hardware status, channel faults, and alarm conditions for easy diagnostics. The card supports hot-swappable installation for hassle-free maintenance and works

in tandem with IOC4T input/output cards to deliver 0-10V voltage or 4-20mA current analog outputs, seamlessly integrating with upper-level control systems.

Compliant with international standards like IEC 61508 and ISO 13849, it operates reliably in harsh industrial environments and is widely used in power

generation, petrochemical, and manufacturing sectors to prevent unplanned downtime and support predictive maintenance.

204-040-100-011 System racks

The 204-040-100-011 System Rack is a foundational 6U 19-inch enclosure designed exclusively for the VM600 Series machinery protection and condition

monitoring systems, featuring a robust aluminum construction ideal for industrial cabinet or panel mounting. It incorporates an integrated VME backplane that

enables seamless electrical interconnection between installed modules, supporting signal processing, data acquisition, power distribution, and communication

via the VM600 Series’ tacho, raw signal, and open collector buses. With capacity for up to 15 single-width VM600 Series cards (or a combination of multi-width

modules) and space for one or two RPS6U power supplies, it offers flexible configuration options—including power redundancy where one supply automatically

takes over if the other fails to ensure uninterrupted operation. A built-in power supply check relay at the rear provides real-time status indication, while its

modular design allows for customized expansion with protection and monitoring cards to meet specific application needs. Compatible with the full range of

VM600 Series components, this rack operates reliably in harsh industrial environments and is widely used in power generation, petrochemical, and

manufacturing sectors to support centralized equipment health management.

Contact:Cheryl Qi

Phone No: +8618150137565

Email: chen@htechplc.com

Whatsapp: +8618150137565

Website:https://www.joyyparts.com/

Recommended Model