Introduction

The SPEEDTRONIC™ Mark VI turbine control is the current state-of-the-art control for GE turbines that have a heritage of more than 30 years of successful

operation. It is designed as a complete integrated control, protection, and monitoring system for generator and mechanical drive applications of gas and steam

turbines. It is also an ideal platform for integrating all power island and balance-of-plant controls. Hardware and software are designed with close coordination

between GE’s turbine design engineering and controls engineering to insure that your control system provides the optimum turbine performance and you

receive a true “system” solution. With Mark VI, you receive the benefits of GE’s unmatched experience with an advanced turbine control platform.

Triple Redundancy

Mark VI control systems are available in Simplex and Triple Redundant forms for small applications and large integrated systems with control ranging from a

single module to many distributed modules. The name Triple Module Redundant (TMR) is derived from the basic architecture with three completely separate

and independent Control Modules, power supplies, and IONets. Mark VI is the third generation of triple redundant control systems that were pioneered by GE in

1983. System throughput enables operation of up to nine, 21-slot VME racks of I/O cards at 40 ms including voting the data. Inputs are voted in software in a

scheme called Software Implemented Fault Tolerance (SIFT). The VCMI card in each Control Module receives inputs from the Control Module back-plane and

other modules via “its own” IONet.

Application Specific I/O

In addition to general purpose I/O, the Mark VI has a large variety of cards that are designed for direct interface to unique sensors and actuators. This reduces or

eliminates a substantial amount of interposing instrumentation in many applications. As a result, many potential single-point failures are eliminated in the most

critical area for improved running reliability and reduced long-term maintenance. Direct interface to the sensors and actuators also enables the diagnostics to

directly interrogate the devices on the equipment for maximum effectiveness. This data is used to analyze device and system performance. A subtle benefit of

this design is that spare-parts inventories are reduced by eliminating peripheral instrumentation. The VTUR card is designed to integrate several of the unique

sensor interfaces used in turbine control systems on a single card. In some applications, it works in conjunction with the I/O interface in the Backup Protection

Module described below.

Operator Interface

The operator interface is commonly referred to as the Human Machine Interface (HMI). It is a PC with a Microsoft® Windows NT® operating system supporting

client/server capability, a CIMPLICITY® graphics display system, a Control System Toolbox for maintenance, and a software interface for the Mark VI and other

control systems on the network. (See Figure 3.) It can be applied as:

■ The primary operator interface for one or multiple units

■ A backup operator interface to the plant DCS operator interface

■ A gateway for communication links to other control systems

■ A permanent or temporary maintenance station

■ An engineer’s workstation

Software Maintenance Tools

The Mark VI is a fully programmable control system. Application software is created from inhouse software automation tools which select proven GE control and

protection algorithms and integrate them with the I/O, sequencing, and displays for each application. A library of software is provided with general-purpose

blocks, math blocks, macros, and application specific blocks. It uses 32-bit floating point data (IEEE-854) in a QNX operating system with real-time applications,

multitasking, prioritydriven preemptive scheduling, and fast context switching.

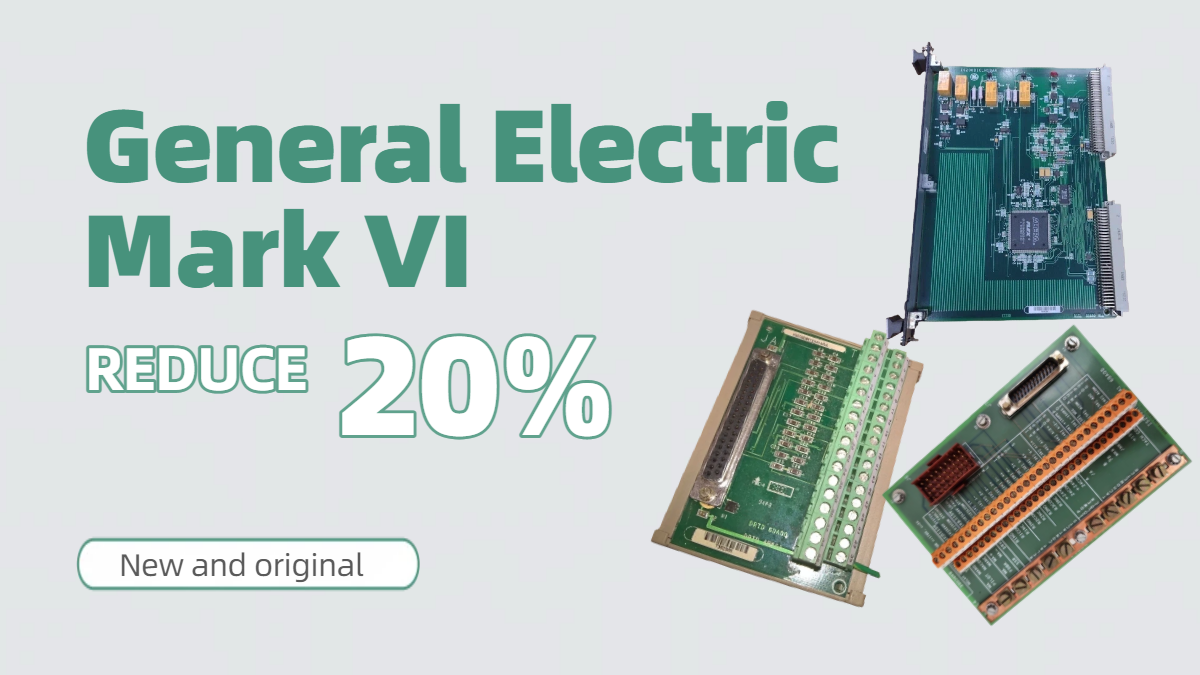

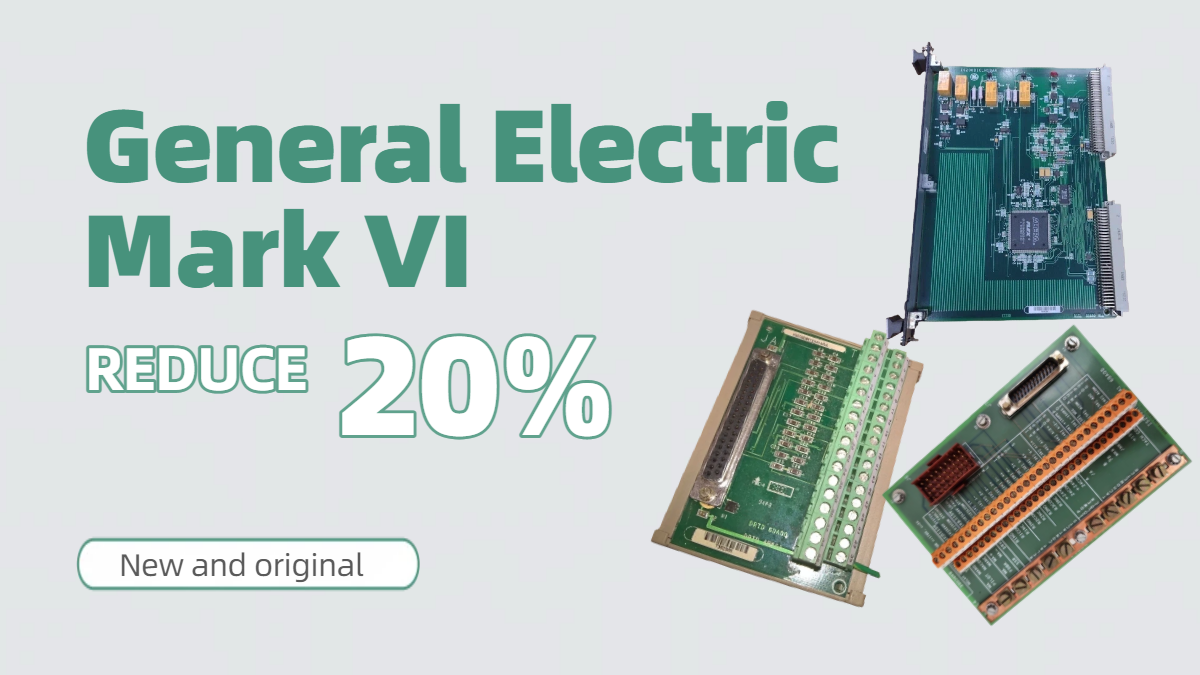

IS20ATBAG1BAA1 is an Aplication inputoutput Terminal Board Manufactured and Designed by General lectric as part of the Mark Vle Series used in G Drive

TurbineControl systems. it is a crucial component within General Electic's innovation Series,incorporaing features like a Windows 200/xp-based operator

interface, Ethemetand Cs communications, and Cimplicity software. Terminal Board foms a critical part of General lectric's lnovation Series, ofering an operator

interfacecommunication capabilities, and sofware integration.The board featres various connectors with diferent voltage ratings for /6 and 7,necesitating

attention to thesvaniations duing handing or replacement. Additionall,adherence to safety protocols, such as electrical circuit testing before replacement, is

hiohly recommended tomitigate potential risks during maintenance procedures involving the board.

FAQ

What is an Application Input/Output Terminal Board?

An Aplication lnput/Output Terminal Board, commonly referred to as an /0 Terminal Board, is a hardware component used in varous electronic systems to

manage thinput and output functionalities. It acts as an interface between the system's central processing unit and external devices or peripherals.

Where are l/O Terminal Boards commonly used?

I0 Terminal Boards find aplications in various industries and systems,incuding industrial automation, proces control,robotics,automotive

electronics,aerospace,aninstrumentation.

What types of input and output signals can an l/0 Terminal Board handle?

Depending on the specific design and application requirements,an /0 Terminal Board can handle a wide range of signals, including analog voltage/current,

digital logisignals, frequency/pulse inputs, temperature, pressure, and various sensor outputs.

A key product characteristic of the IS200BICLH1BAA is its robust design for high-reliability environments. The architecture of the IS200BICLH1BAA provides

essential signal conditioning and electrical isolation for sensitive control systems. Furthermore, the IS200BICLH1BAA module offers field-configurable input

voltage settings, enhancing its application flexibility across different project requirements.

Application Scenarios

The IS200BICLH1BAA serves as a critical hardware component of the Mark VI control system, and its application scenarios are highly consistent with those of the

Mark VI series. It is widely used in the control systems of gas and steam turbines in fields such as power generation, petrochemicals, and heavy industry.

Whether it is small - scale simple turbine control systems or large - scale integrated control systems with triple redundancy configurations, this board can

effectively undertake interface communication and signal conversion tasks, helping to improve the reliability and control accuracy of turbine operation. It plays

an indispensable role in ensuring the continuous and stable operation of key energy equipment and reducing operational risks.

IS210DRTDH1A is an RTD input Terminal Board developed by GE.lt is part of the GE spedtronic Mark Vl gas turbine controlsystem. This terminal board is

responsiblor colecting and transmiting temperature data fom RtD sensors to the sustem's prcesor board,ensuing accurate thermal montorng and control of

tutbine components and auxiliary systems.

FAQ

What is IS210DRTDH1A?

lt is an RTD Input Terminal Board and is part of the GE Mark Vl gas turbine control system.

How many RTD inputs does the board support?

Each board supports 8 RTD inputs. Two boards can be connected to a VRTD processor board for a total of 16 temperature inputs.

How is the board installed?The board is mounted on a DIN-rall using a plastic holder. RiD sensor wires connect directly to the 36-terminal Euro-Block, with

teminals 25-34 reserved as sparesTerminals 35 and 36 are for the SCOM (ground) connection, which should be kept as short as possible.

What type of wiring is recommended?

18 AWG shielded twisted trilet wires are tyicaly used to connect RTDs to the temminal board, ensying accurate signal transmision and minimizing electical noise.

How are faults indicated and cleared?Diagnostic faults trigger composite alarms such as L3DlAG xox.Hardware faults can be latched and reset using REET DlA,

while system limit faults can be dleared withRESET SYS. In TMR systems, limit logic is voted across controllers to provide a composite diagnostic output.

Can the boards be stacked to save space?

Yes, the DRTD terminal boards can be stacked vertically on the DiN-rail, optimizing control cabinet space without affecting functionality.

Hot-selling recommended models(Click the item number to see the details)